Ac’s Engineering Ltd. understands that the surface finish of an engine block is critical and it can be hard to replicate consistently block after block after block after block. Our engine block boring in Jamaica technicians have been trained to calibrate and maintain our machines to ensure that the bore of the cylinder/engine block is within factory specifications.Thats one of the reasons we chose the Rottler H85A CNC Automatic Vertical Honing Machine which is the Rolls Royce of CNC engine block polishing/honing. This honing machine gives true, constant and accurate crosshatch finishing angles the entire length of the cylinder block bore with machine feeding stones to specified load during the honing process and withdrawing the stones automatically before stopping.

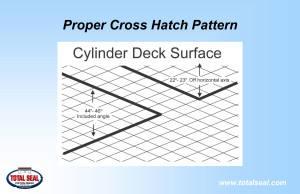

Cross-hatch angles of the engine block bore help determine ring rotation speed and also how easily oil is moved up and down the cylinder bore. Most typical applications run a 45-degree cross-hatch angle.

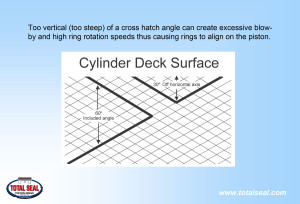

Some very long stroke engines will run a steeper angle, as steep as 60 degrees in an attempt to move oil to the top of the bore. Steeper angles tend to hasten oil removal from the cylinder wall. Also, if the cross-hatch angle becomes too steep it creates blow-by and high ring rotation speeds, causing them to align adversely on the piston.

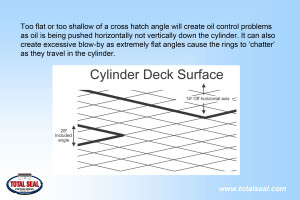

Many high-end race engines run flatter 30-35 degree angles. The flatter the angle the harder it is to expel the oil.

Modern cylinder honing/polishing is confirmed by measurements: Rpk, Rk and Rvk

Harder engine blocks and affordable profilometers—the devices that precisely measure the surface finish of the cylinders—have changed honing procedures immensely and with it our understanding of oil retention and ring seal. Even the measuring standard Ra (arithmetic average of roughness) is becoming obsolete, being replaced by three more effective standards: Rpk (Peak roughness); Rk (Core roughness) and Rvk (Valley roughness found below the core roughness).

Majority of machine shops in Jamaica are honing engine blocks much rougher than they think. When you have a rough bore it retains too much oil for modern light-tension low-drag racing rings and they cannot seal correctly and consequently burn oil because of inadequate honing. On the other hand, if oil retention is insufficient metal-to-metal scuffing occurs which leas to the engine block being work quickly or being damaged in a very short period. The main objective is to have just the correct amount of oil retention in the cylinder walls after the ring scrapes it down—and this is achievable with a profilometer.